In the world of making things very precisely, Poland is standing out more and more. It’s known for its CNC machines and tech. This area thrives on the expert hands of Polish workers who have become very skilled over time1. They make sure to produce top-notch CNC parts. This push for new ideas goes hand in hand with a strong focus on CNC programming and tech. The importance of this field is also shown by how much it helps the country’s GDP1. There’s also a growing need for CNC parts that keeps increasing across the country1.

CNC machining in Poland really shows the perfect teamwork between humans and machines. These services don’t just help local makers but also play a big role in Europe’s economy. A lot of these perfectly made parts are sent to other EU countries1. It’s clear why the focus on quality and always trying to be better are key to Poland’s success in CNC machining.

Introducing CNC ALFA: Your Partner for CNC Machining Excellence

In the world of precision manufacturing, CNC ALFA stands out in Poland. With a focus on CNC turning and CNC milling, they use cutting-edge technology. They have experts ready to handle complicated tasks. CNC ALFA offers personalised services. They strive to meet the unique demands of clients across Europe. They also ensure timely delivery of top-notch CNC parts.

About CNC ALFA

CNC ALFA is dedicated to top quality assurance. They follow strict ISO 9001:2015 standards. This sets them apart as highly committed to excellent manufacturing. Clients really trust them.

Commitment to Quality and Timeliness

CNC ALFA focuses on both quality and timeliness. In manufacturing, timing is key. CNC ALFA is great at providing CNC prototypes and parts on time. They never let quality drop.

Diverse Industries Served

CNC ALFA works with many sectors. They serve the defence industry, aerospace industry, and medical industry. They also work in automation and robotics. Their skill in making custom CNC solutions shows they can thrive in various manufacturing areas.

CNC ALFA uses innovative techniques. These methods fit various needs for removing material and enhancing surfaces:

| Methodology | Application | Outcome |

|---|---|---|

| TOPSIS method | Optimization of EDM parameters | Energy-efficient operations with improved Surface Roughness (Sr) |

| Taguchi design concept | Analysis of milling effects on Aluminum 1100 | Optimised Material Removal Rate (MRR) and finer Surface Roughness (SR) |

| Fuzzy logic in decision-making | Handling imprecise assessments | Enhanced qualitative output variables |

These methods show CNC ALFA’s drive to lead in precision machining. Experts in the field have seen the benefits of these advanced techniques2.

Comprehensive CNC Services Across Poland

CNC ALFA steps into the CNC manufacturing world, offering top-notch precision and flexibility. They’re opening new doors for customized machining across Poland. They’re known for innovative CNC services like milling and turning, which meet diverse industry needs.

Modern CNC systems have changed production by automating it with cutting-edge CAD and CAM software. This change began in the 1940s and 1950s with the first CNC machines. These machines now play a key role in boosting quality and efficiency in Poland’s manufacturing, combining different manufacturing methods into innovative hybrid techniques3.

Metal Machining and Beyond

Covering Major Polish Cities

CNC Machining

The start of CNC machines in the 1940s and 1950s began a new phase in manufacturing. Motors changed existing tools to automate them with punched tape4. CNC technology improved productivity by reducing the need for manual work45. CNC systems aim for accuracy, speed, and consistency, now using advanced controls4.

CNC machining has transformed metal fabrication, offering high accuracy and efficiency. It allows 24/7 operations with little oversight and quicker production times5. It also cuts material waste, saving costs for makers5. CNC is key in aerospace, auto, electronics, and medicine for making complex or once-impossible components5.

| Industry | Application of CNC Machining |

|---|---|

| Aerospace and Aviation | Engine parts, landing gear, and other critical components |

| Automotive | Engine parts, gears, advancements in electric vehicle manufacturing |

| Electronics | Electronic components, intricate cuts for circuit boards |

| Medical | Medical devices, implants, surgical instruments |

Innovative CNC Milling and Turning Solutions

The CNC manufacturing world is quickly changing, with CNC milling Poland leading the way. This field is growing strongly, showing a impressive 7% increase every year for five years. Businesses aim to boost efficiency and add more tech to their operations6.

State-of-the-Art Equipment and Capabilities

Modern technology and gear are key for this industry’s growth. Top names like Mazak, Doosan, and DMG Mori bring precision components and CNC technology to life in important tasks.

Custom Milling Specifications

Custom milling combines flexibility with accuracy. CNC ALFA, for example, can work on big projects with sizes up to 4000 x 2000 x 1070 mm. These services are tailored to what clients need, showing CNC milling Poland’s dedication to custom solutions.

Precision Turning Services

CNC turning services are evolving with a focus on fine details. They can handle sizes up to 1000 mm for CNC turning and 3000 mm for traditional turning. This adaptability helps meet the exact needs of different industries.

In the global market, Poland’s CNC machining has grown by 25% in exports. This shows the world wants the high-quality machining services from here6. CNC turning and milling are key to this success.

Quality Assured with ISO 9001:2015 Certification

The International Organization for Standardization has created over 18,000 standards. Among them, ISO 9001:2015 is key for setting up a solid quality management system7. It’s crucial in various fields like precision manufacturing and CNC machining. At its heart, it relies on seven key principles guiding companies to excellence and outstanding customer service78.

Firms adopting ISO 9001:2015 practices see big advantages. They’ve got better survival rates, sales boosts, more jobs, and higher wages than those who haven’t8. Also, these companies show better overall performance, proving the real benefit of quality assurance on their operations and customer happiness8.

The ISO 9001:2015’s focus is on constantly getting better. This is done by closely watching customer satisfaction and evaluating both inputs and outputs7. Managers play a big role by looking out for risks and thinking ahead to avoid problems7. This dedication helps keep precision manufacturing ahead in both innovation and quality.

ISO 9001:2015’s impact goes beyond just internal tasks; it boosts tech too. It allows for more rapid prototyping thanks to gear like 3D printers for making custom parts. In Poland, CNC machine and mill tech among certified firms shows their high precision in every item they make8.

To wrap up, ISO 9001:2015 certification is all about committing to quality. It betters CNC machining and precision making worldwide. By following this standard’s principles, businesses not only ensure great quality but also build strong customer relationships. They lay a foundation of trust and reliability for their future78.

Precision Prototyping and Custom CNC Services

Poland’s industrial sector is changing fast, focusing more on specialized markets thanks to advances in CNC machining9. CNC ALFA and CNC Connect Poland are leading this change. They offer detailed prototype services for the automotive, aerospace, and medical sectors9. The need for top-quality precision parts is growing. These companies help drive the development of custom machining and prototypes in Poland9.

The world of custom CNC prototyping is transforming. More service providers mean more competition9. These organisations are not just helping the local economy. They also create technical jobs9. To support this, the Polish government provides financial help through the Tarcza Antykryzysowa program. This helps these services keep going during tough times9.

From Idea to Execution

Companies in Poland are turning ideas into real objects through custom CNC services9. They invest in modern equipment to meet high industry standards. This commitment ensures that every prototype is of the highest quality9. This approach has created a thriving environment. Here, CNC machinists and programmers help the industry focus on niche markets9.

Rapid Prototyping for Faster Development

The Polish CNC prototyping sector stays on top of global trends and tech advancements9. By using innovative manufacturing techniques, they keep up with international standards. This not only improves rapid prototyping but also speeds up product development9. This means faster from concept to market-ready products. It gives clients the edge with quick updates and improvements9.

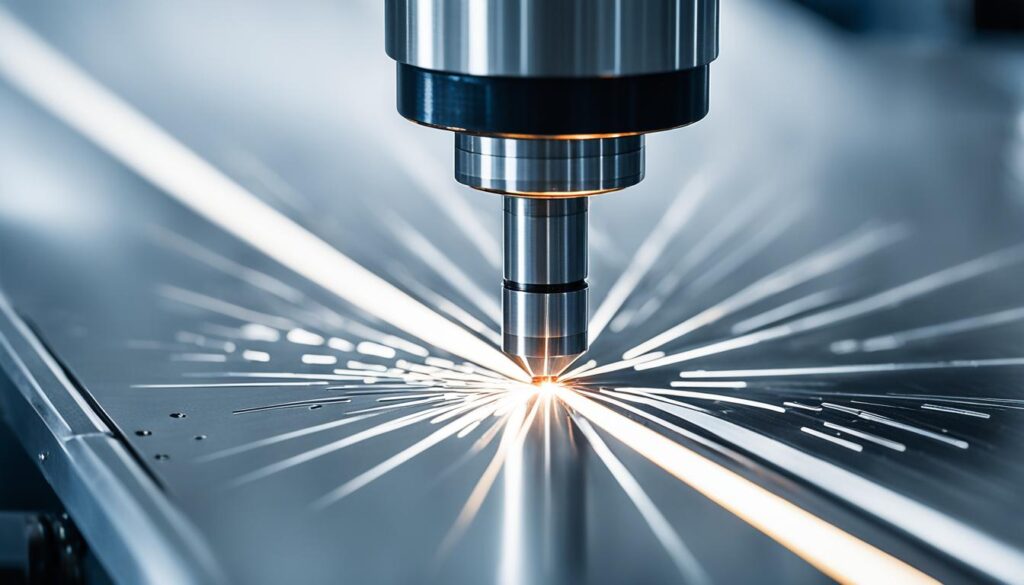

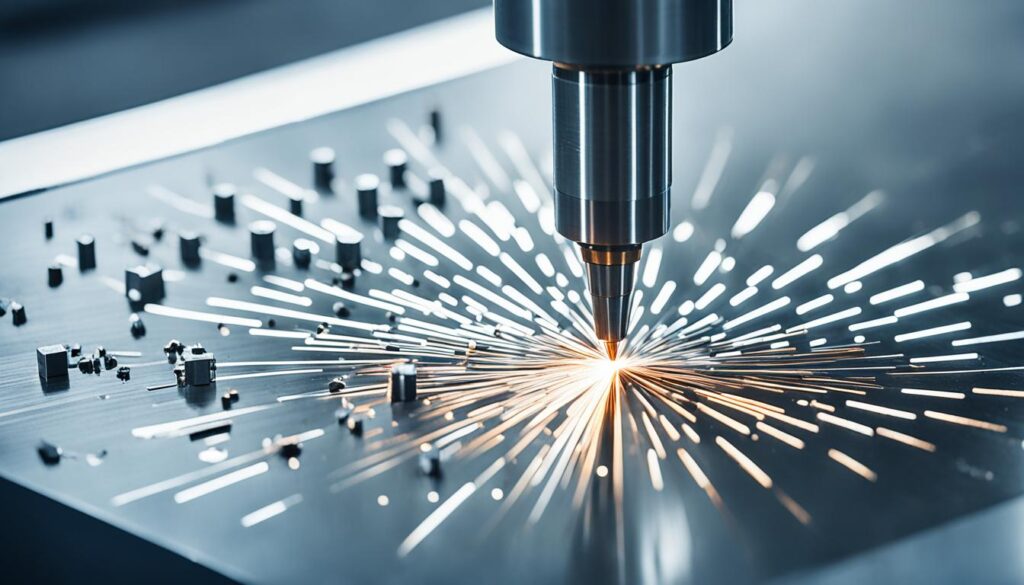

Advanced Metal Cutting and Finishing Technologies

Today’s precision engineering is all about advanced metal cutting techniques. This includes CNC, laser, plasma, and waterjet cutting. Each method brings precision and flexibility to the table. With these, we can craft metal parts with great care. Modern laser cutting can handle many materials. It’s fast and precise, cutting at speeds up to 8,000 m/min10.

New materials for cutting tools have reached hardness up to 9000 HV. They also have toughness over 1000 MPa. This boosts cutting speed and how quickly we can feed materials into the machines10. Precision in machining is now so fine it’s down to 10 µm for regular methods. Some even reach ultra-precision of under 0.1µm10. Since the 1940s, technology has dramatically improved. Ultra-precision CNC machines now boast accuracies up to 1nm10.

Laser, Plasma, and Waterjet Cutting

Our CNC machining sector handles a wide range of materials today. It’s about meeting quality needs and being flexible. Aluminum is used in consumer goods, transportation, and building. Yet we’re also using engineered plastics and composites. These materials are cost-effective. They don’t conduct electricity. And, they help in making devices, medical supplies, and scientific gear11. Steel and brass are getting upgraded too. Alongside these, composites are helping the aerospace industry. They make planes lighter which saves fuel12.

Heat Treatment and Coating Expertise

Precision engineering doesn’t stop at cutting metal. Heat treatment and coatings also play a huge role. They make metal parts stronger and look better. Case hardening is one way to harden surfaces. Anodising and powder coating fight corrosion. They also make parts look good for their final use. CNC Connect Poland’s precision and expertise mean they perfect every metal piece. They represent the best in precision engineering.

Robust Global Shipping and Export Services

Since 1961, John Pipe International has led the way in global shipping. They focus on various industries, like exporting carefully made CNC parts. This company aims high, showing its vast knowledge in moving goods across borders for over 60 years13.

Their sea freight solutions include Full Container Load (FCL) and Less than Container Load (LCL). They also handle special items like Out of Gauge (OOG) or dangerous materials. These special services show their deep understanding of the shipping world’s challenges13.

John Pipe International takes extra steps to keep goods safe on their journey. They offer tracking services for peace of mind13. This careful tracking ensures CNC parts reach international clients safely and on time.

Sea freight is more than just moving goods for John Pipe International. It’s a full package that includes loading containers, ensuring security, and helping with documentation. This makes sure everything follows shipping rules13.

They also share knowledge through articles and resources. This helps businesses understand sea and international freight better. By doing this, they show their commitment to excellent customer service in shipping and exporting CNC parts13.

Conclusion

Poland has become a key player in manufacturing, thanks to its top-notch CNC machining services. These services are known for making precision CNC parts better than many others. Their machines can make huge parts, much bigger than what 3D printers can do14. They work with great precision, achieving accuracy within ±0.025 mm. This showcases Poland’s amazing engineering skills14.

The Polish CNC scene is also dedicated to making materials with a smooth finish. The surface of machined polymer parts is very fine, at 3.2 µm, beating the quality of 3D printed parts14. For big orders, Polish CNC services show their strength by producing lots of parts fast without mistakes14. CNC is also more cost-effective when making more than 10 units14. The finishing touches, like bead blasting and dyeing, turn these parts into works of art14.

CNC ALFA and CNC Connect Poland embody the peak of custom CNC solutions. They are committed to maintaining high manufacturing standards. They manage projects with skill, whether they’re for Poland or the wider world. As leaders in Poland’s manufacturing scene, they show what’s possible when you aim for precision in CNC machining.

Source Links

- https://www.gov.pl/web/poland-and-cnc-machining-collaboration

- https://iopscience.iop.org/article/10.1088/2631-8695/acfdf4

- https://en.wikipedia.org/wiki/Computer_numerical_control

- https://en.wikipedia.org/wiki/Numerical_control

- https://wisconsinmetaltech.com/the-benefits-of-cnc-machining-for-metal-fabrication/

- https://www.usa.gov/

- https://www.linkedin.com/pulse/top-5-customer-benefits-iso-9001-certified-cnc-machining-james-abbott?trk=portfolio_article-card_title

- https://www.spex1.com/iso-90012015-certification/

- https://www.gov.pl/web/kprm/-/polish-precision-cnc-machining-business-seeking-customers-abroad

- https://escholarship.org/content/qt7hd8r1ft/qt7hd8r1ft_noSplash_2e0884fc6f99caff5fa7a2a98d18849c.pdf?t=krn71d

- https://jp-murphy.com/blog/cnc-machining/

- https://wisconsinmetaltech.com/the-future-of-cnc-machining/

- https://www.johnpipe.co.uk/freight/sea-freight/

- https://xometry.pro/en-eu/articles/cnc-machining-polymers/